MMO Titanium Anode

MMO (Mixed Metal Oxide) Titanium Anode is a type of metal oxide anode made of mixed metal oxides, often including a combination of titanium and other metal oxides such as ruthenium, iridium, or niobium. The area of the mesh is 1.2 x or even more than that of the equivalent strong plate electrode.

- Shown dependability

- Incredibly long life and easy to maintain

- Can be easily installed in any environment

- Corrosion Resitant

- Cost effective compared to other materials

| Metal Substrate | Titanium Gr1, Gr2, TA1, TA2 |

|---|---|

| Coating | Platinum(Pt), Ruthenium Oxide (RuO2), Iridium Oxide (IrO2), Ru-Ir |

| Current Range | <8000A/㎡ |

| Coating Thickness | 0- 20 µm |

| Substrate Type | Mesh, Wire, Plate, Sheet, Tube, Rod |

Details about MMO Titanium Anode

Product Details

Size & Application

How to order

Video

Product Details

MMO Titanium Anode

The Expanded Metal Anode is a device with high conductivity as well as corrosion resistance for use as anodes in electrolysis. They are made by layer a substratum, such as a pure titanium plate or increased mesh, with a number of type of metal oxides. One oxide is normally RuO2, IrO2, or PtO2, which performs electricity and also catalyzes the wanted response such as the manufacturing of chlorine gas.

It is used in a wide range of electrochemical applications, such as cathodic protection in a variety of industries including marine, oil and gas, water and wastewater, power and energy, and infrastructure. It is highly corrosion resistant, and offers good longevity, stability, and an efficiency in electro-chemical reactions

MMO Titanium Anode Advantages

- Increased throughput with reduced plating times

- It offers better efficiency and performance in a variety of applications such as electroplating, cathodic protection, and electrolysis

- Excellent adherence properties with proper surface preparation

- Lightweight and Energy savings

- Outstanding mechanical strength (Anti-ravel and Flexible)

- Outstanding chemical resistance to highly acidic conditions – typical for oxygen and chlorine evolving environments common in many cathodic protection applications

Application Field

- Cathodic Protection and Electroplating and cathodic protection

- Electrolysis of Water

- Electrolytic Metallurgy

- Organic Synthesis

- Sewage treatment plants

- Electrosynthesis/chlorate and perchlorate production

- Electroplating Industry

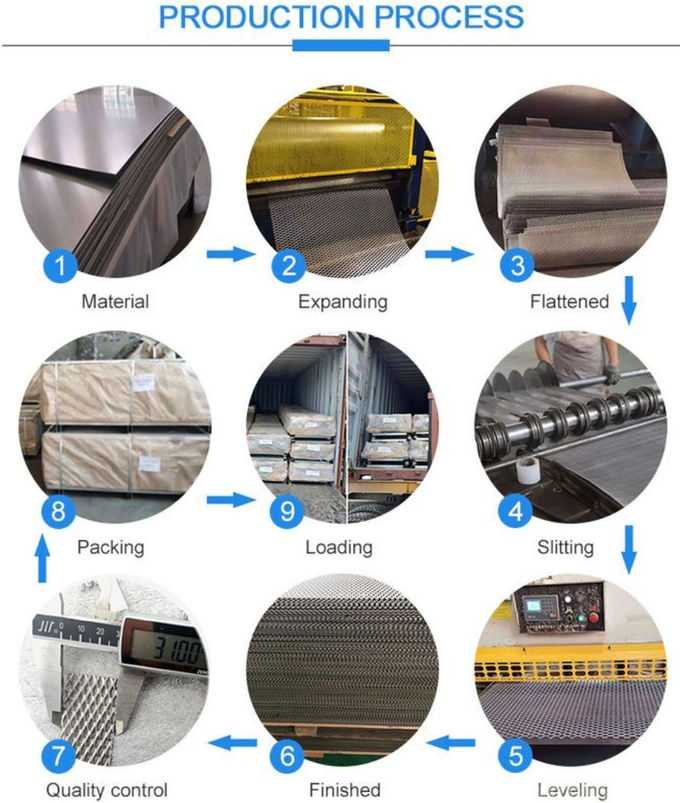

Process Scheme

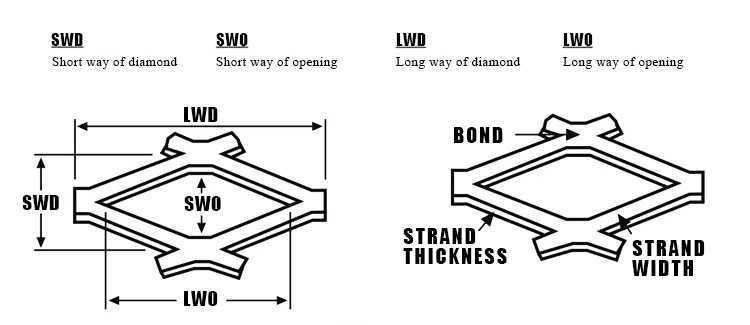

Terminology

-

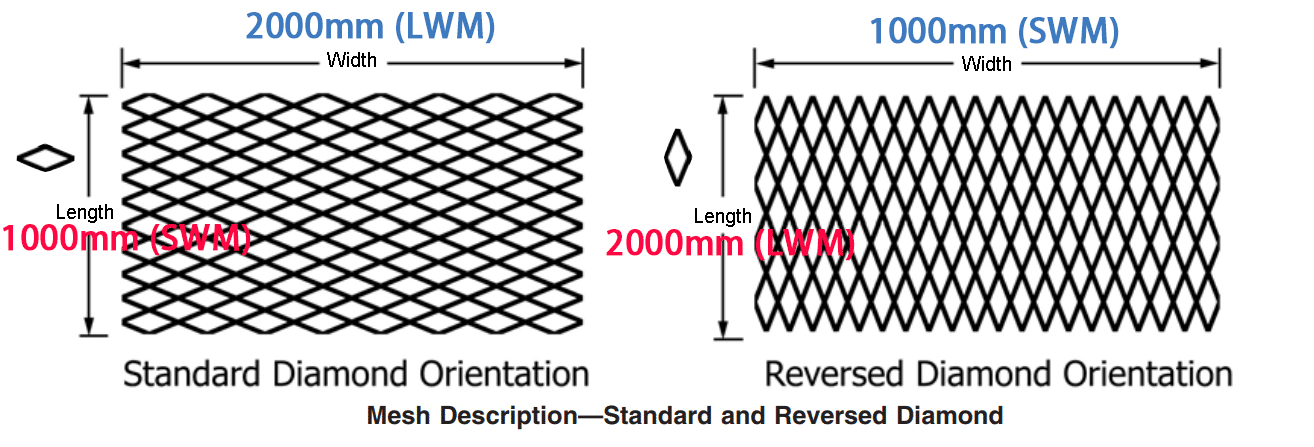

SWD: Short Way of Diamond LWD: Long Way of Diamond

-

SWO: Short Way of Opening LWO: Long Way of Opening

-

Flattened Expanded Metal V.S Standard Expanded Metal

1.1 Expanded Metal Terminology:

1.1.1 bond, n-the solid intersection of two strands.

1.1.2 camber, n-the bow of a side or edge from end to end from a straight line.

1.1.3 diamonds, n-open area of metal after expanding.

Most expanded metal open areas or patterns are uniform diamond-shaped, but may also be hexagonal, louvered, asymmetric, square, or other shapes, or combinations thereof.

1.1.4 edge configuration, n-refers to the edge condition of a sheet may they be closed diamonds (bonded), or open diamonds (random) produced by shearing.

1.1.5 expanded metal, n-a rigid sheet of metal that is simultaneously been slit and stretched creating an open diamond pattern.

1.1.6 flattened, v (F)-expanded metal that has been cold rolled after expansion.

1.1.7 flattening, adv-the process of producing flattened expanded metal.

1.1.8 grating, n-expanded metal that is produced from heavier sheets.

1.1.9 levelness, n-(flatness of sheet), sheets shall be free from waves or buckets that are in excess of 1–1/2 in. from a plane surface.

1.1.10 LWD, n-nominal dimension, Long Way of the Diamond.

1.1.11 LWO, n-Long Way of the Opening.

1.1.12 regular-raised-standard, n-(R) expanded metal as it comes from the press. The strands and bonds are set at a uniform angle to the plane of the sheet.

1.1.13 SWD, n-nominal dimension, Short Way of the Diamond.

1.1.14 SWO, n-Short Way of the Opening.

1.1.15 shearing, n-cutting the sheet to a specific size or tolerance.

1.1.16 squareness, n-the dimensional variance a side and edge are out of square.

1.1.17 strand thickness, n-thickness of the base metal.

1.1.18 strand thickness, n, and strand width, n-can be varied to create different expanded metal products for different applications.

1.1.19 strand width, n-amount of material fed through top and bottom dies to produce one strand.

1.1.20 taper, n-edges of a sheet that deviates from parallel

Titanium Anode Packing & Shipping

How to calculate the weight of expanded metal?

Please check our special expanded metal weight calculator.

Size & Application

Popular Size

| Popular Size (mm) | ||

|---|---|---|

| Thickness | Strand Width | Long Way of Diamond |

| 0.051 | 0.102 | 0.787 |

| 0.102 | 0.152 | 0.787 |

| 0.127 | 0.254 | 3.175 |

| 0.178 | 0.178 | 3.175 |

| 0.254 | 0.305 | 3.175 |

Applications

- Cathodic Protection and Electroplating and cathodic protection

- Electrolysis of Water

- Electrolytic Metallurgy

- Organic Synthesis

- Sewage treatment plants

- Electrosynthesis/chlorate and perchlorate production

- Electroplating Industry

How to order

How to order mmo titanium anode?

Please Specify:

- Material: Titanium, Gr1, Gr2, etc.

- Type: Standard/Raised, Flattened

- Quantity: number of pieces – full size or cut pieces required

- Piece Size: width (SWD) x length (LWD)

- Shearing: bond or random. Please check the below photo for reference

- Finish: Pt coating, special, if any

Item No.: typically expanded metal is specified like the following examples:

1/8 #23 S 3′ SWD x 6′ LWD Titanium Gr 1

- – 1/8 inch= Short Way Of Diamond Dimension

- – #23 = Gauge (Usually not AWG, BWG, SWG, should be Washburn & Moen)

- – “S” = Standard (“F” would indicate flattened)

- – 3′ SWD x 6′ LWD = size of sheet width x length

- – Titanium Gr 1 = material

The Best Wire Gauge Chart

You may also provide us the plate thickness in mm

| Gauge | American Wire Gauge(AWG) mm | Washburn & Moen mm | Birmingham Wire Gauge(BWG) mm | Standard Wire Gauge(SWG) mm | United States Standard mm |

|---|---|---|---|---|---|

| 7/0 | 12.446 | 12.7 | |||

| 6/0 | 14.732 | 11.722 | 11.786 | ||

| 5/0 | 13.119 | 10.935 | 10.973 | 11.113 | |

| 4/0 | 11.684 | 10.003 | 10.16 | 10.319 | |

| 3/0 | 10.404 | 9.208 | 9.449 | 9.525 | |

| 2/0 | 9.266 | 8.407 | 8.839 | 8.731 | |

| 1/0 | 8.252 | 7.785 | 8.23 | 7.938 | |

| 1 | 7.348 | 7.188 | 7.62 | 7.62 | 7.144 |

| 2 | 6.543 | 6.668 | 7.213 | 7.01 | 6.747 |

| 3 | 5.827 | 6.19 | 6.579 | 6.401 | 6.35 |

| 4 | 5.189 | 5.723 | 6.045 | 5.893 | 5.953 |

| 5 | 4.62 | 5.258 | 5.588 | 5.385 | 5.556 |

| 6 | 4.115 | 4.877 | 5.156 | 4.877 | 5.159 |

| 7 | 3.663 | 4.496 | 4.572 | 4.47 | 4.763 |

| 8 | 3.261 | 4.115 | 4.191 | 4.064 | 4.366 |

| 9 | 2.906 | 3.767 | 3.759 | 3.658 | 3.969 |

| 10 | 2.586 | 3.429 | 3.404 | 3.251 | 3.572 |

| 11 | 2.304 | 3.061 | 3.048 | 2.946 | 3.175 |

| 12 | 2.052 | 2.68 | 2.769 | 2.642 | 2.778 |

| 13 | 1.826 | 2.324 | 2.413 | 2.337 | 2.381 |

| 14 | 1.626 | 2.032 | 2.108 | 2.032 | 1.984 |

| 15 | 1.448 | 1.829 | 1.829 | 1.829 | 1.786 |

| 16 | 1.29 | 1.588 | 1.651 | 1.626 | 1.588 |

| 17 | 1.148 | 1.372 | 1.473 | 1.422 | 1.429 |

| 18 | 1.024 | 1.207 | 1.245 | 1.219 | 1.27 |

| 19 | 0.909 | 1.041 | 1.067 | 1.016 | 1.111 |

| 20 | 0.81 | 0.884 | 0.888 | 0.914 | 0.953 |

| 21 | 0.721 | 0.805 | 0.813 | 0.813 | 0.873 |

| 22 | 0.643 | 0.726 | 0.711 | 0.711 | 0.794 |

| 23 | 0.572 | 0.655 | 0.635 | 0.61 | 0.714 |

| 24 | 0.511 | 0.584 | 0.559 | 0.559 | 0.635 |

| 25 | 0.455 | 0.518 | 0.508 | 0.508 | 0.556 |

| 26 | 0.404 | 0.46 | 0.457 | 0.457 | 0.476 |

| 27 | 0.358 | 0.439 | 0.406 | 0.417 | 0.437 |

| 28 | 0.32 | 0.411 | 0.356 | 0.376 | 0.397 |

| 29 | 0.284 | 0.381 | 0.33 | 0.345 | 0.357 |

| 30 | 0.254 | 0.356 | 0.305 | 0.315 | 0.318 |

| 31 | 0.226 | 0.335 | 0.254 | 0.295 | 0.278 |

| 32 | 0.201 | 0.325 | 0.229 | 0.274 | 0.258 |

| 33 | 0.178 | 0.3 | 0.203 | 0.254 | 0.238 |

| 34 | 0.16 | 0.264 | 0.178 | 0.234 | 0.218 |

| 35 | 0.142 | 0.241 | 0.127 | 0.213 | 0.198 |

| 36 | 0.127 | 0.229 | 0.102 | 0.193 | 0.179 |

| 37 | 0.112 | 0.216 | 0.173 | 0.169 | |

| 38 | 0.099 | 0.203 | 0.152 | 0.159 | |

| 39 | 0.089 | 0.191 | 0.132 | ||

| 40 | 0.079 | 0.178 | 0.122 | ||

| 41 | 0.071 | 0.168 | 0.112 | ||

| 42 | 0.063 | 0.157 | 0.102 | ||

| 43 | 0.056 | 0.152 | 0.091 | ||

| 44 | 0.05 | 0.147 | 0.081 | ||

| 45 | 0.045 | 0.14 | 0.071 | ||

| 46 | 0.04 | 0.132 | 0.061 | ||

| 47 | 0.036 | 0.127 | 0.051 | ||

| 48 | 0.031 | 0.122 | 0.041 | ||

| 49 | 0.028 | 0.117 | 0.03 | ||

| 50 | 0.025 | 0.112 | 0.025 |

Shearing Type

Expanded Metal Mesh Direction

Video